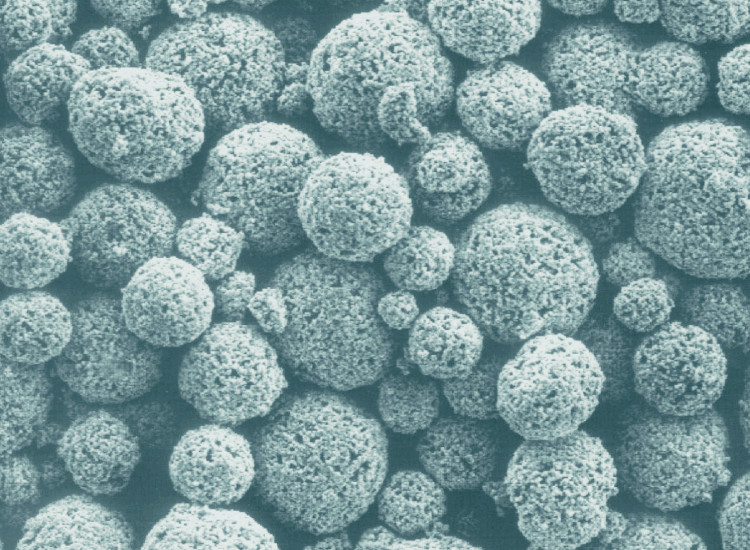

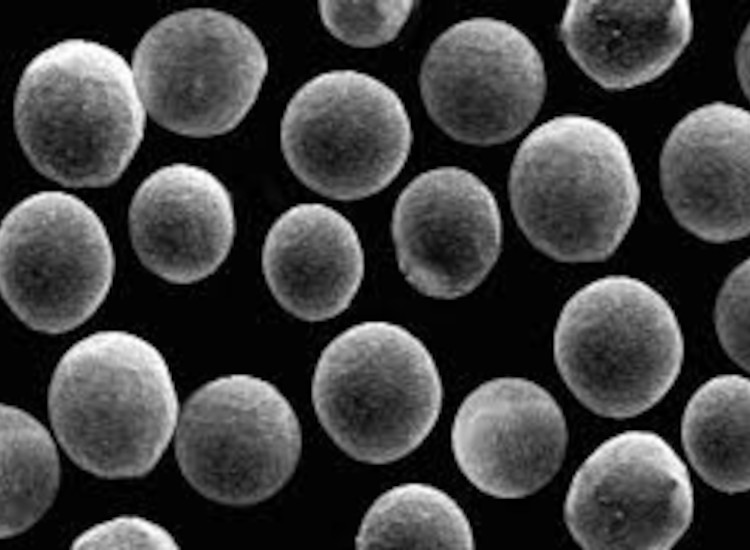

Powders for thermal spray applications

GreenEco offers a full range of high quality powder materials for all surface treatment processes, including thermal spray technologies, PTA and laser cladding.

This includes powders for:

- thermal spray (plasma, HVOF, HVAF, flame spray (cold and hot),

- cladding/welding (PTA, laser cladding, microplasma),

- special welding technologies.

Our standard offer includes nickel (Inconel), cobalt (Stellites), iron and copper-based powders, metallic and carbide blends, agglomerated and fused, solid spherical and crashed carbides and other complex carbides powders from WC-Co, WC-Ni, WC-Cr-Co groups , Cr3C2-NiCr for supersonic, plasma and flame spraying.

GreenEco can also develop and deliver customized powder materials with properties optimized for customers individual needs. As a representative of world known manufacturers of thermal spray powders, GreenEco can offer very high quality materials that will produce coatings with absolutely superior properties. Our materials are used by the largest OEM companies around the world, including Aerospace/Aircraft and PowerGen sectors.

GreenEco offers high-quality materials, the composition of which is specially optimized for specific potential applications, for example, equipment repair, component surface hardening, increasing component’s surface resistance to abrasive wear, corrosion, erosion, high temperature protection and others equipment damage mechanisms, common for all production environments.

We offer less expensive but excellent quality replacements for materials such as Stellite, Inconel, EuTroLoy, RotoTec, ProXon, Metco and others. Our materials are used in all types of industries, for the protection and repair of machine parts, including some of the most challenging applications typical for the Aero and Power Gen sectors.

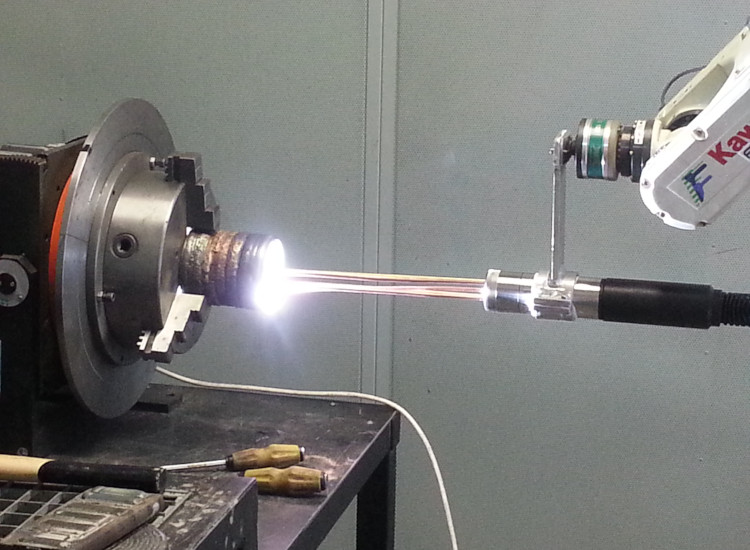

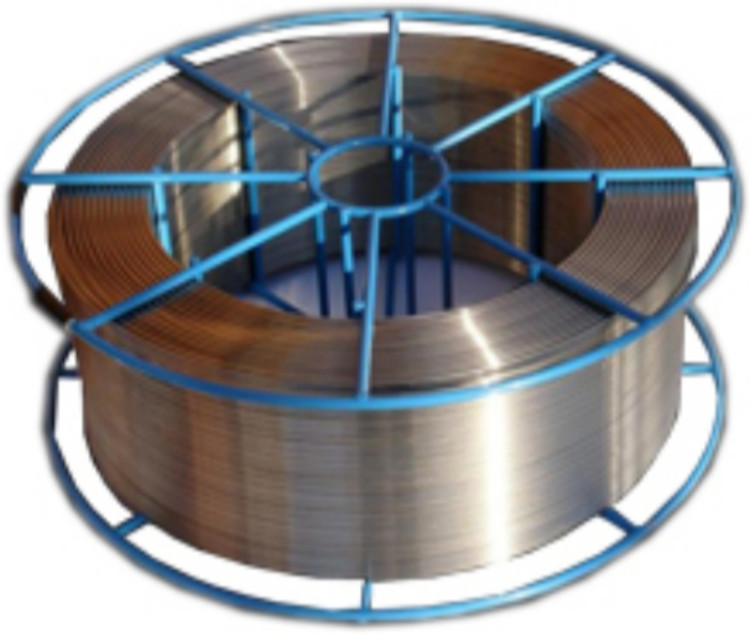

Thermal Spray and Welding Wires

GreenEco offer includes a wide range of the highest quality wires for all welding and thermal spraying processes. We can supply both, solid and cored wires, including flux cored wires. These materials are being widely used to protect and extend the lifetime of new components and to repair worn and/ or damaged equipment.

Main applications for the wire-feed thermally sprayed coatings include:

- Increased resistance to abrasion and erosion

- protection against oxidation and chemical corrosion, for both, room and high temperature applications

- reduction or increase of the friction coefficient

- decorative coatings

- other specialized applications

Our wide range of products include pure metal and alloy wires based on:

- Nickel

- Cobalt

- Iron

- Molybdenum

- Aluminum

- Copper

Our experienced technical personnel is always ready to assist clients with the material selection that will best match the requirement for even the most challenging applications.

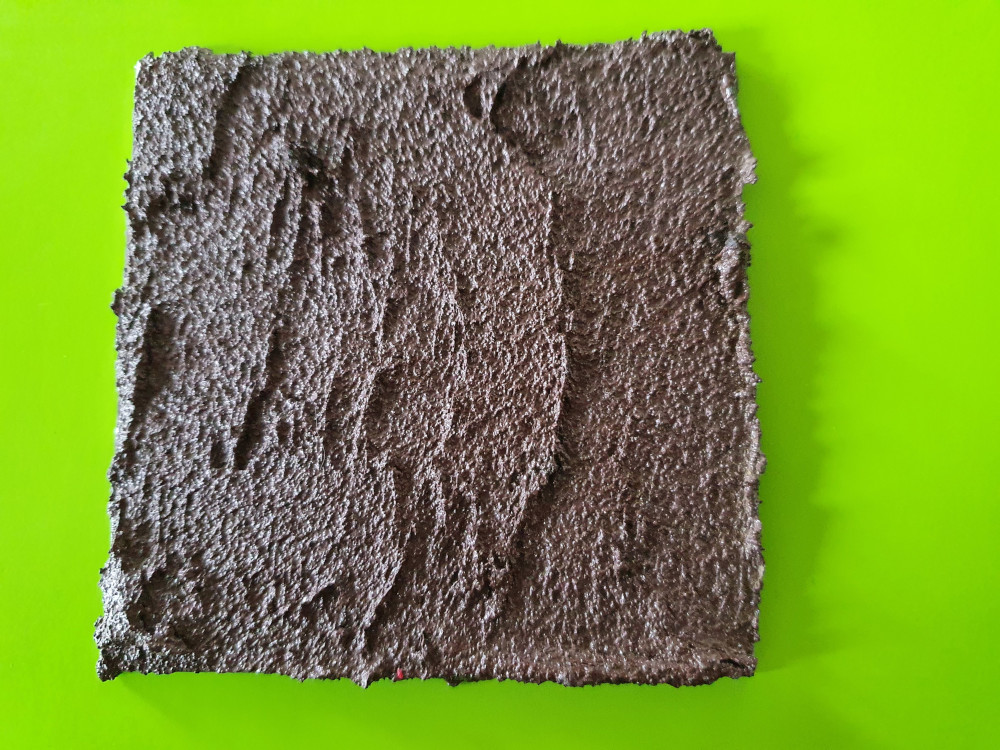

Wear Resistant Compounds and Ceramic Binders

GreenEco offer specialized ceramic pastes for industrial applications, including the protection of surfaces exposed to severe erosive and corrosive conditions, for both room and high temperature applications. Depending on their composition, pastes can be used as materials for local repairs of machine elements, sealing elements, or as materials protecting the surface of equipment against abrasion, erosion and/ or corrosion or as adhesives.

Our offer includes products manufactured by the absolute industry leaders – SCP and Aremco. Ceramic pastes and finished ceramic components include materials based on silicon carbides, alumina, aluminum silicates, boron nitride, ceramic glasses, magnesium oxide, zirconium oxide and zirconium phosphate. The pastes are characterized by an excellent bond with the metallic, ceramic or polymeric surfaces. These materials can withstand high surface pressure and will seamlessly operate in a wide temperature range. They are resistant to thermal shocks and chemical attack.

SCProbond™ compounds

SCProbond™ A/CRC is a trowel-on silicon carbide filled, abrasion and corrosion resistant wear compound designed for thick application on badly worn areas or known severe wear locations. The unique formula of A/CRC forms a tough high performance barrier that resists sliding abrasion and chemical attack. A/CRC adheres easily to most metals and cast silicon carbide substrates found in harsh processing environments.

SCProbond™ WRC is similar to our A/CRC, however this product is more of a general purpose abrasion resistant compound for wear protection formulated for areas that see less than 150°C and where severe corrosion is not an issue. WRC is designed for use in pump casings, slurry lines, pipe elbows, pneumatic transport systems, chutes, cyclones, fans, coal breakers, pulverizers, coal heads, and other high wear areas.

Epoxy & Cement Products:

SCProbond™ A/CRC is a trowel-on silicon carbide filled, abrasion and corrosion resistant wear compound designed for thick application on badly worn areas or known severe wear locations. The unique formula of A/CRC forms a tough high performance barrier that resists sliding abrasion and chemical attack. A/CRC adheres easily to most metals and cast silicon carbide substrates found in harsh processing environments.

SCProbond™ HT-1 is a high temperature potting cement that maintains bond strength at temperatures up to 1100°C. HT-1 resists oil, electricity, most solvents, and all acids except hydrofluoric. SCProbond™ HT-1 demonstrates incredible peel strength that requires a heat cure for best results.

SCProbond™ HT-3 is a similar high temperature cement typically used as a backing material to fill voids behind the ceramic on circular tile installations such as those found in burner applications within coal fired power plants. This product has service temperatures up to 954°C and cures at ambient temperatures. HT-3 resists oil, electricity, most solvents, and all acids aside from hydrofluoric.

SCProbond™ LV-1 is a non-corrosive low viscosity epoxy system suitable for horizontal applications that see less than 95°C and designed for installation of SCProbond™ liners as well and similar material handling components.

SCProbond™ HV-1 is a similar adhesive also formulated for installation of SCProbond™ liners. The high viscosity of this adhesive makes it ideal for vertical, and overhead applications, such as tiling on ceilings and sidewalls. SCProbond™ HV-1 is specially formulated for installing SCProbond™ material handling components.

Customer Testimonial

“Since we installed the new screw, production was so good, we had to restrict flow to maintain quality.”

-Limestone Mine Operator and Returning SCP Customer

The erosion and wear resistance of the silicon carbide layers is comparable to that of the hardfaced carbide layers. The ease of application and the possibility of applying the compounds to hard-to-reach places make SCP pastes an excellent alternative to the competitive abrasion-resistant products. High-temperature ceramic-metal compounds are frequently used to seal joints and/ or to repair defects in aluminum, cast iron, steel and stainless steel. These innovative materials are designed to operate at temperatures up to 1090ºC (2000 ° F). These materials are widely used in the aerospace, automotive, mining, foundry, heat treatment, waste incineration and power industries.

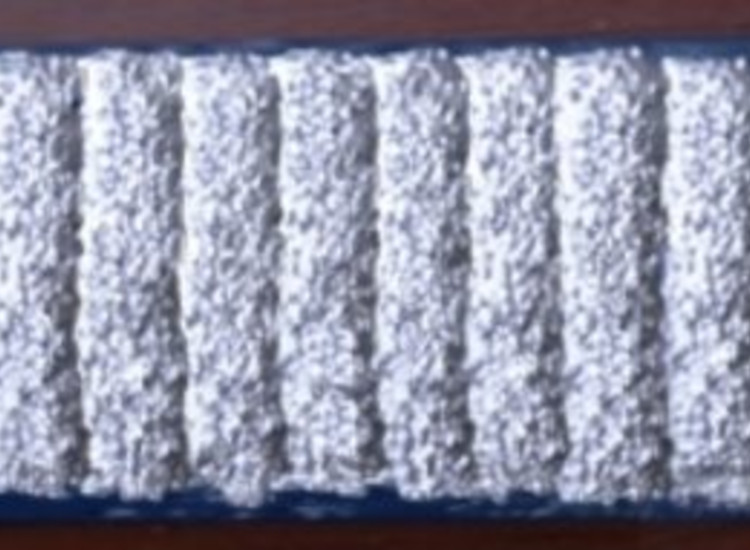

Thermal spray masking tapes

GreenEco’s superior quality masking tapes, are used to protect surface areas that cannot be coated with thermally sprayed coatings. Thees tapes are characterized by excellent temperature resistance, therefore they provide effective surface protection in thermal spraying processes, including HVOF / HVAF, plasma, arc spraying and flame spraying processes. They perfectly adapt to the surface, they are characterized by high adhesion to metal and to the surface of the tape itself, which prevents the subsequent layers from peeling off; after their removal no adhesive residue is left on the surface. All our products are certified by the major OEMs manufacturers, which makes them perfect products for applications in the aerospace/aircraft, power generation, food, refineries, chemical and other industries.

Ceramic and graphite adhesives and binders

GreenEco offer includes a range of advanced adhesives and binders for various industrial applications to be used on a range of surface materials. They produce excellent high strength bonds that are resistant to a wide range of temperatures and chemicals. The high temperature adhesives are used for making strong inter-component joints in detonators, lamps, heaters, sensors, etc. Our high-temperature ceramic and graphite adhesives are uniquely formulated compounds for joining dissimilar materials such as ceramics, composites, graphite, metals, quartz and semiconductors, in applications up to 1760°C.

We also offer adhesives for temporary assembly of products that will be cut, polished and subjected to other processing. These adhesives exhibit high bond strength and connect easily with metals, glasses and ceramics. They are easily removed by heating and cleaning with one of our environmentally friendly cleaners.