Kermetico HVAF systems and technology

HVAF – Description of the High Velocity Air-Fuel Spraying Process

Kermetico High-Velocity Air-Fuel Spraying (Kermetico HVAF) is a process for deposition of high-quality coatings of metals, alloys, cemented carbides and borides onto metallic surfaces.

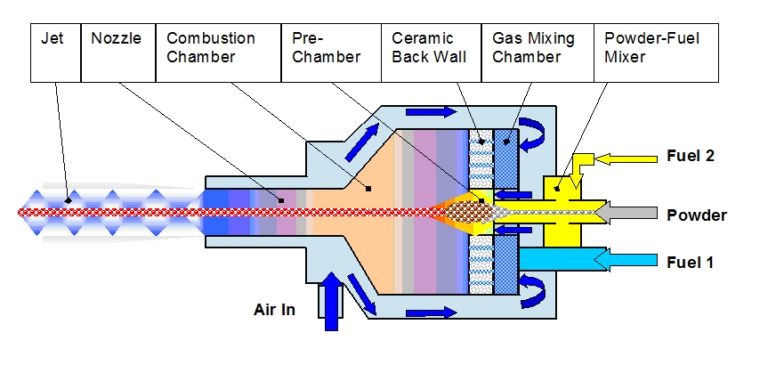

The coating material in the form of pre-alloyed or composite powder is fed into a Kermetico HVAF spray gun. The gun combusts compressed air and fuel gas (propane, propylene, natural gas, etc.) generating a high-velocity jet of combustion products. In the jet, the spray powder is heated and accelerated and, when impacting a workpiece (substrate), forms a coating.

The quality and efficiency of the Kermetico systems family is the result of the relatively low combustion temperature of the air-fuel mixture combined with the axial injection of the feedstock through the long combustion chamber, where the low gas velocity provides sufficient time for the powder particles gradual heating. The materials’ acceleration occurs in the nozzle that has a large diameter. The large diameter of the nozzle is needed to pass through the volume of nitrogen present in the combustion air. It also assures that the nozzle walls do not interact with the particles, allowing the use of a nozzle that is as long as needed for feedstock acceleration, typically from 800 to over 1,200 m/s. The Ceramic Catalytic Insert is used in the combustion chamber to provide a wide range of stable combustion parameters.

Precise temperature control of the spray material near the melting point and high impact velocities are the distinguishing characteristics of the Kermetico HVAF coating deposition process.

A diagram of the Kermetico HVAF configuration

Quality of the HVAF coating

The combustion temperature in air-fuel mixtures is typically 1000°C lower than in oxygen-fuel combustion. This lower temperature is ideal for the gradual heating of the feedstock particles of metals and cemented carbides to or slightly above the metals’ melting temperature.

The initial oxygen content in the combustion gas mixture is 5-fold lower in the HVAF process compared to any HVOF process. Both factors prevent the oxidation of metals and the decomposition of carbides and their dissolution into the metal binder. These factors allow the retention of the original ductility of the powder feedstock material in the applied coating, even when the hardness of the cemented carbide coating exceeds 1700 HV300.

Kermetico HVAF Systems

The Kermetico AK HVAF system deposits coatings with 5-6 times higher spray rate, 20-30% higher deposition efficiency, 30% less deviation than any HVOF system. Choosing Kermetico AK, an HVOF job shop gains at least 50% cost advantage to HVOF competitors and additional coating quality advantage as a “bonus.”*

| WC/Co/Cr coating feature | Typical HVOF | Kermetico HVAF Mode | ||

| Economy | Balanced | Ultra-quality | ||

| Deposit efficiency, % | 40-55 | 60-70 | 48-58 | 36-42 |

| Hardness, HV300 | 1050-1250 | 1050-1250 | 1250-1350 | 1350-1600+ |

| Apparent metallographic porosity | below 0.8 | below 0.8 | below 0.8 | below 0.8 |

| Bond strength, PSI (MPa) | 80+ | |||

| Range of as-sprayed roughness, μm | 3.5-4.5 | 1-3.2 | ||

Kermetico AK can also deposit Ag, Al, Cu, Sn, Ti and other powder materials that are “unusual” for HVOF.

Oxidant and coolant: Compressed Air. Pressure range 8-11.5 bar (115-165 PSIG).

Fuel: Propane, Propylene, Propane-Butane (LPG), or Natural Gas. Pressure: 7-11.5 bar (100-165 PSIG).

| Kermetico AK HVAF spray guns | Gun | Description | Max spray rate, per hour |

| AK7 | Large parts with diameter above 200 mm (8”) | 33+ kg / 72+ lbs. |

| A powerful gun with the widest range of combustion chamber pressures and the best coating quality on large surfaces. The lowest cost for large surfaces. The best protection against feedstock oxidation. | |||

| AK6 | Universal carbide gun for parts Diameters 5-250 mm (0.2”-10”) | 28 kg / 62 lbs | |

| The gun designed to spray tungsten carbide on a wide spectrum of parts. 70% of AK7 power. | |||

| AK5 | Miniature gun for smaller parts | 15 kg / 33 lbs. |

| Spraying metals, alloys, and carbides for parts below 200 mm diameter, ID from 200 mm (8”) up, thin walls, complex surfaces. | |||

| AK-HH | Manual HVAF spraying of complex surfaces | 15 kg / 33 lbs. |

| The universal hand-held gun is supplied with a robot mounting fixture. Used for spraying metals, alloys, and carbides. Gun weight: 2.5 kg (5 lbs.) | |||

| AK-ID | Internal diameters minimum 80 mm (3.15”) | 5 kg / 11 lbs. |

| Air cooling provides hours of continuous ID operation. Spray angle 90°. | |||

| AK-ID | Rotating head, minimum diameter 100 mm (4”) | 5 kg / 11 lbs. |

| Air cooling provides hours of continuous ID operation. Spray angle 90°. | |||

Each gun, except for our ID guns, may be configured to Ultra (highest velocity), Economy (highest DE), or Balanced mode and they may be used in blast & spray mode.

Kermetico Control Consoles and Powder Feeders

Selected features of Kermetico AK Systems

- Industrial IP67-rated Tablet + PLC Controller;

- Unlimited number of stored programs;

- One system fits all guns;

- Variety of powder feeders and gas vaporizers;

- Custom-made systems and guns by request;

- And more.

Kermetico HVAF equipment distribution

Since our incorporation in 2006, we have installed more than 60 HVAF systems worldwide. Some of the systems are at work in Universities and National labs, but most of them are used in production by coating shops.

Our systems can be equipped with different guns; they are robust and technologically efficient. And they are not expensive. If you spray tungsten carbide for just 3 hours per day, our system pays back your investment in only three months.

Since our incorporation in 2006, we have installed more than 60 HVAF systems worldwide. Some of the systems are at work in Universities and National labs, but most of them are used in production thermal spray shops. Our systems can be equipped with different guns; they are robust and technologically efficient. And they are not expensive. If you spray tungsten carbide for just 3 hours per day, our system pays back your investment in only three months.

Please contact Green Eco at www.greeneco.com.pl for more information on the HVAF equipment and its potential application

We are looking forward to doing business with You!